Our production process

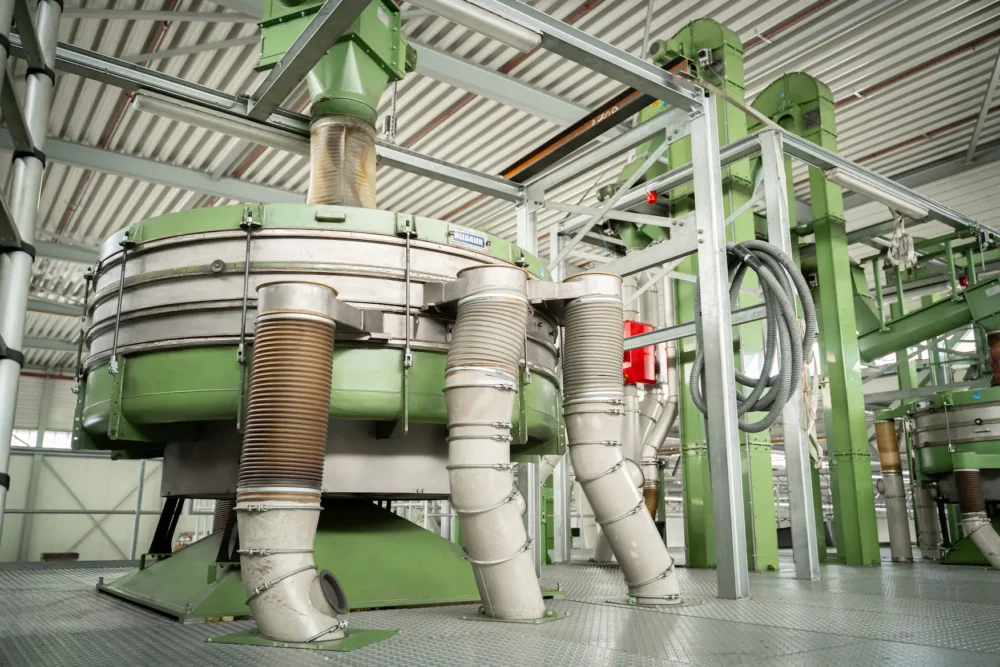

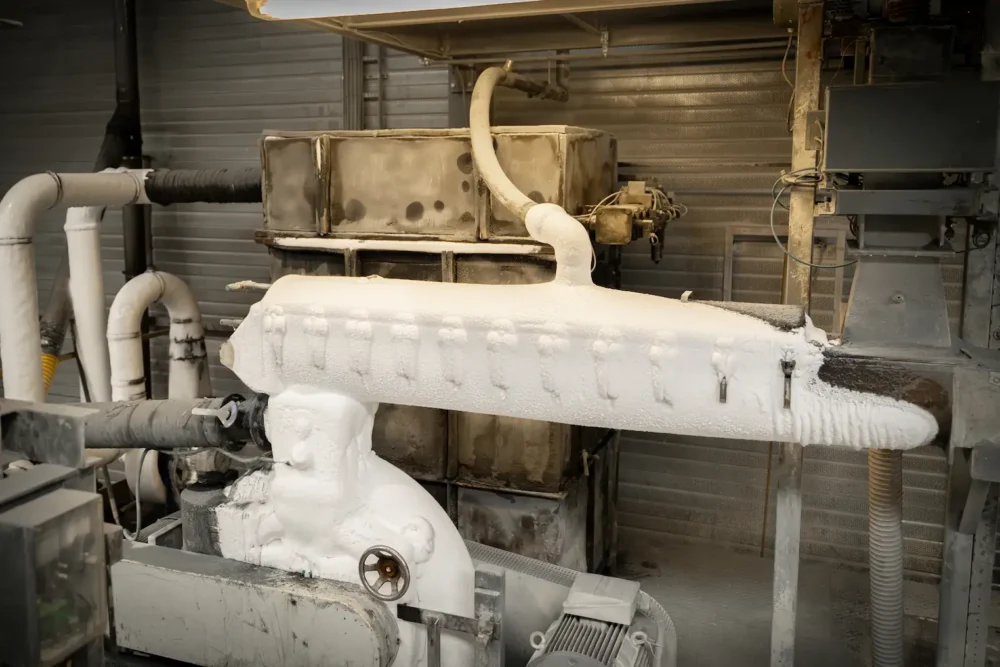

Since 1947, we have continuously optimised our rubber recycling and processing production process to turn (unsuitable) rubber waste into a usable semi-finished product. With our sophisticated production process, we convert as much as 99.99% of waste. Minimal loss, maximum profit.

Rubberbuffings

Rubber powdersand granulates

Rubber raw materials and semi-finished products

We process the recycled rubber into a wide range of rubber raw materials and semi-finished products. We also offer toll grinding, where we grind pure waste into rubber powder and return it as a raw material to make a new end product, such as new rubber compounds, sports and play floors, sound insulation systems and garden mulch. Cheaper than new rubber and better for the environment.

- Rubber Buffings

- Rubber Powders

- Rubber Granulates

- Rubber Compounds

- Inner Tubes

End products and customized rubber products

We also process the recycled rubber into new end products. For example, we sort by hand a stream of inner tubes, in order to press them into rubber straps and pallet bands.

- Rubber Pallet Straps

- Rubber Straps

- Textile Straps

- Anti-slip mats

- Pallet ropes

- Cellular Rubber Tape

Tailor-made

Rubber is a rewarding material because of its unique properties, such as flexibility, insulation, shock absorption and heat and water resistance. Which rubber product is the solution for your industry? Ask us for advice. We are happy to use our more than 75 years of knowledge and experience to think along with you.

Do you have a question?

Would you like to know more about our production process, or are you curious whether we can make your product from rubber? Get to know us to see what we can do for each other.